I had been doing some work lately and found some good ways on how to drill properly. I wanted to create a tutorial about properly performing this task but I thought I needed to actually make it into an article to make it interesting.

Using power tools can make a tough job much easier. Nevertheless, they may also make simple tasks more dangerous. Because of that, I will provide you with safety tips and guides on how to drill properly and extend the life of your tools.

Most Workers Don’t Know How to Drill

It’s surprising for me how many workers don’t know how to do things as simple as drilling the right way.

Drills are amongst the most famous power tools for workers, but there are several steps that have to be followed as drilling can get a little confusing. Drills are used in nearly all DIY and home improvement projects, but do you really know how to use a drill order to maximize its effectiveness?.

And They End Up Messing Everything

For me, drilling in the correct way does not only mean that you will get the right hole in the right place, but you will also be able to get it with the least amount of trouble and without having to damage your tools, materials, and yourself.

So.. remember to follow this step by step guide on how to drill exactly so you know you are doing things the right way for you, your tools, and your home project or job.

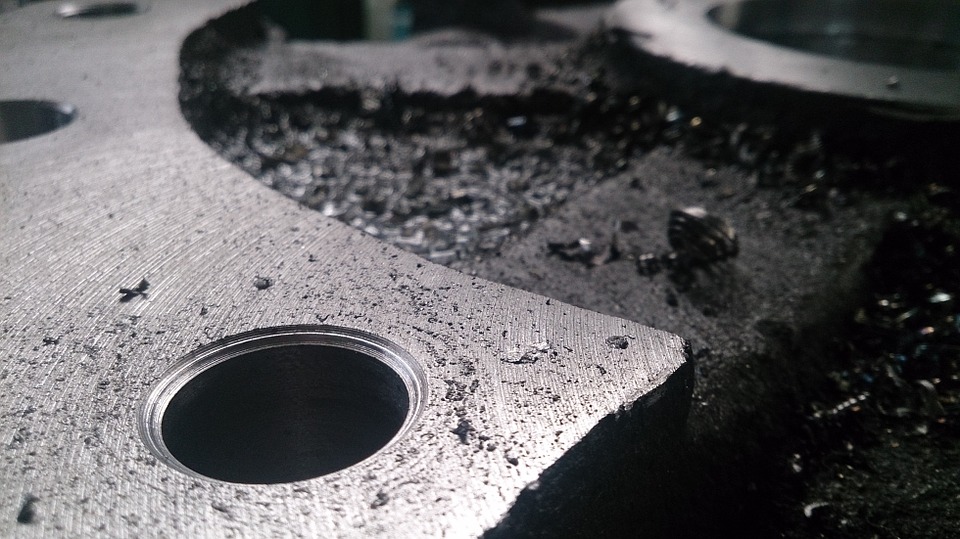

Choose the correct drill bit

In my experience, I have been able to drill soft materials safely with mostly any bit, but I noticed that brittle and hard materials like acrylic or glass might need particularly designed bits.

There are drill bits that are designed especially to produce clean and precise holes, with others being rough but cheap and fast.

Drill with steady pressure and a balanced position

Before starting to drill, I suggest you to make sure that you would completely tighten the drill bit in the chuck, ensuring that it is straight or you will break it. The drill bit needs to be remain straight because it will spin and turn or wobble toward a blurry cone. If it is certainly rightly chucked, the bit might have been bent, and thus, needs to be discarded.

Let the tool do most of the work and apply steady pressure that is directly parallel to the drill bit. On the other hand, if you are leaning into it but there is nothing happening, the drill bit is either dull or you may be using the wrong type for the material that you are drilling on.

Choose the clutch and avoid overheating the drill

All drills have a twistable collar to be able to adjust the torque, most commonly with a series of numbers on it. The higher the number, the more rational force or torque will be applied by the drill. If you are having difficulty to get the material penetrated, I recommend increasing the torque. Furthermore, if you overdrive the screws, or if you are drilling very deeply, it may get something damaged, so I also recommend lowering the torque in those situations.

When I drill at high speeds or into hard materials, the drill bit encounters a great deal of friction. I learned that it is important to begin at a drill speed that is low, and just get the speed increased if the drill is not moving smoothly. Now if you are drilling into some hard materials, or you are trying to drill lots of holes in any materials, I highly suggest you to slow speeds and occasionally pause so that you can give several seconds for the drill to cool down.

When drilling ceramic, stone, or glass, I always give a steady supply of water to the drill bit in order to keep it cool. I often build a dam out of modeling clay or putty around my drilling area.

It’s All About Simple Logic

Working with power tools like drills is amongst the greatest ways to save effort and time when you have a project at home. The advantages of the modern technology enable jobs to get done faster, especially with workers that pay attention to details to make the project great.

This guide that I provided hopefully helps you on how to drill properly, because I believe that safety starts with proper techniques and simple logic.